Forming collar sizes:

| Bag width |

angle α |

Heighth (H) |

Seam width (W) |

Part A |

Part B |

Part T |

| 30~75 |

25°~60° |

25~100 |

5~10 |

Customized according to

client's special

requirements |

| 75~120 |

25°~60° |

60~150 |

10~15 |

| 120~180 |

25°~50° |

100~220 |

10~20 |

| 180~260 |

20°~45° |

150~300 |

10~20 |

| 260~320 |

20°~45° |

220~360 |

10~25 |

Max size to

1 meter |

20°~45° |

25~large size |

10~large size |

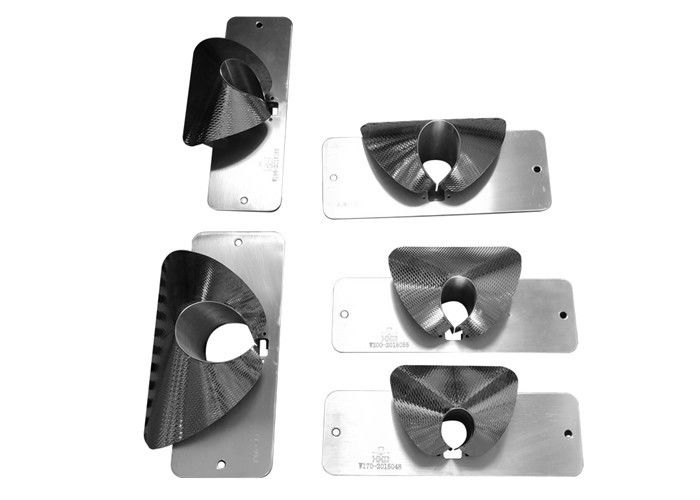

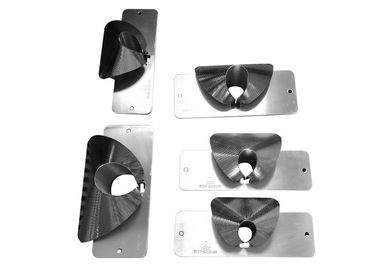

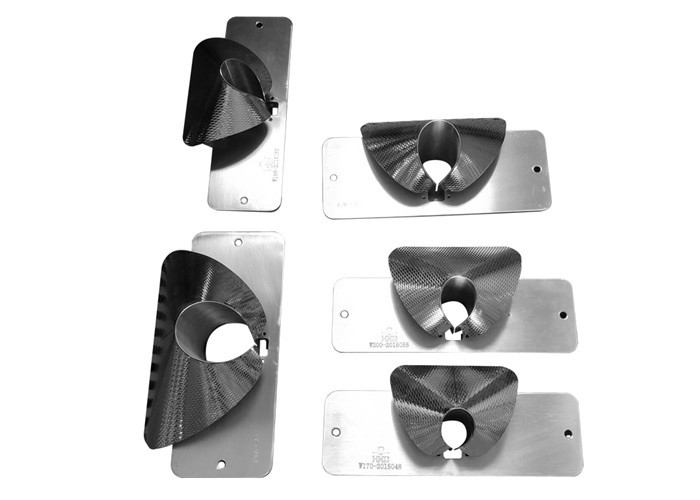

Zhijing Precision Former factory has been manufacturing all kinds of fomrers for more than 25 years. Our vertical former can produce the finishing

bag size as small as 10mm, and as large as 1 meter size.

All our formers are made here are food security standard.

All of the forming collars are made of concavo-convex sus304 plates, reduce the film drag resistance and pull down the films more smoothly and

faster. And we can change the suitable plate's surface according to your special requiremements.

For construction the forming collars, we use the CNC technology to process. With high accuracy, perfct dimensions and surfaces, that makes the

former surpass the world wide's quality.

The forming tube we choose SUS 304 & SUS 316 , for producing the food security tubes. For the tube's thickness, we usually make it 2 - 4mm, if

need different tube thickness, we can also make it.

Every place of the former, we make it the mirror surface, very shining. While when assembling the former, it will be slippery by hands. Then

usually, we use the sand blast coating to the out side tube of the collar, so that when handling the formers, it will be more easy. And after the sand

blasting, the former looks more beautiful.

Your special requirements or any concern for the order, be told us clearly, then we can solve according to your special requirements.

VFFS Packaging machinery Forming Set Shoulder Former Tab Rectangular, round or oval tube forming sets

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!