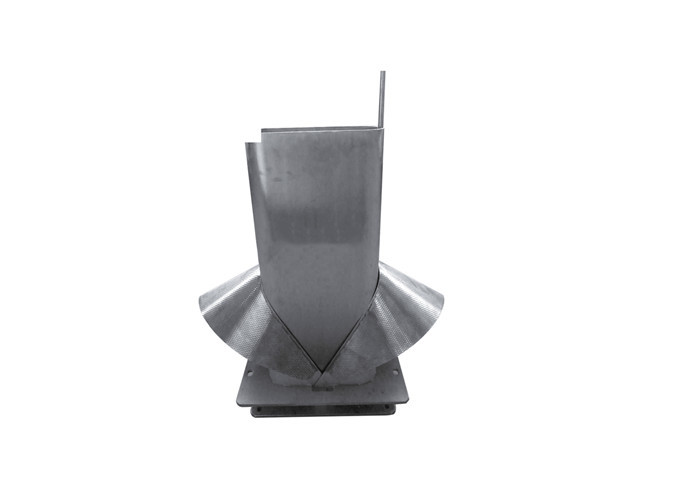

Rec - Oval Tube Forming Collars Packaging Machinery Accessories of Former

We produce the collar's tubes according to your packaging requirements.

Please first offer us the following information, to offer the price:

| Collar Type |

Vertical or Pillow |

| Film or foil width |

Need to be confirmed |

| Seal type |

Need to be confirmed |

| Bag width |

Need to be confirmed |

| Tube type |

Round tube or oval, or square |

| Collar total heighth |

Need to be confirmed |

| Bottom assembling dimensions |

Need to be confirmed |

| Collar photo |

Better offer us if have,

so that we can know better og your required collar |

INNOVATION TO GLOBAL MACHINES

Our technolgical advancements have been innovations that solve our customers' needs.We are worldwide industry changers, and it shows. We

care about your production lines and as a custom fabricator we are equipped to accommodate a wide variety of customer preferences. We

care about your bottom lines, all processes are performed in-house allowing optimal cost control and quality. Innovation with our patented

products and our advanced technology which allows for fast, safe, and precise installation every time.

TRUSTED BY OEMS WORLDWIDE TO FABRIC ATE THEIR FORMERS.

We are better together. Formers for every industry.

The packaging forming collar is the basic part of the vertical form, fill and seal packaging machine.

Our forming collar provides the shape over which packaging film is smoothly formed at high speed into a cylindrical shape.

Describing the forming collar geometry and hence its design is, however, remarkably difficult. While we have been researching the collars for

more than 20 years.

Our productions, for the first time, a flexible methodology for calculating the complete geometry of the film rather than the usually non‐

complete collar over which the film is formed. This means, a methodology to calculate the film geometry over the collar including the seam

along which the film is longitudinally sealed. The film geometry is calculated such that it has minimum deformation energy. Advantages of the

proposed methodology include its great flexibility to generate collars with different configurations for different needs. Among the collar

generation methods reviewed, the proposed methodology is the first that can systematically consider all collar configuration parameters such

as the seam configuration, general package cross‐section, flat or straight part of the collar, collar back angle, etc. A means for obtaining the

exact collar geometry is also demonstrated. This enables right‐first‐time and repeatable collar production and reduces the time and cost for

producing next generation packaging machines.

All of our formers and collar are made of very good workmanship, shining sufaces.

Long working life and very fluent packaging.

Contact us your requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!