We have products former for packaging. Offer us the sizes to get the best price.

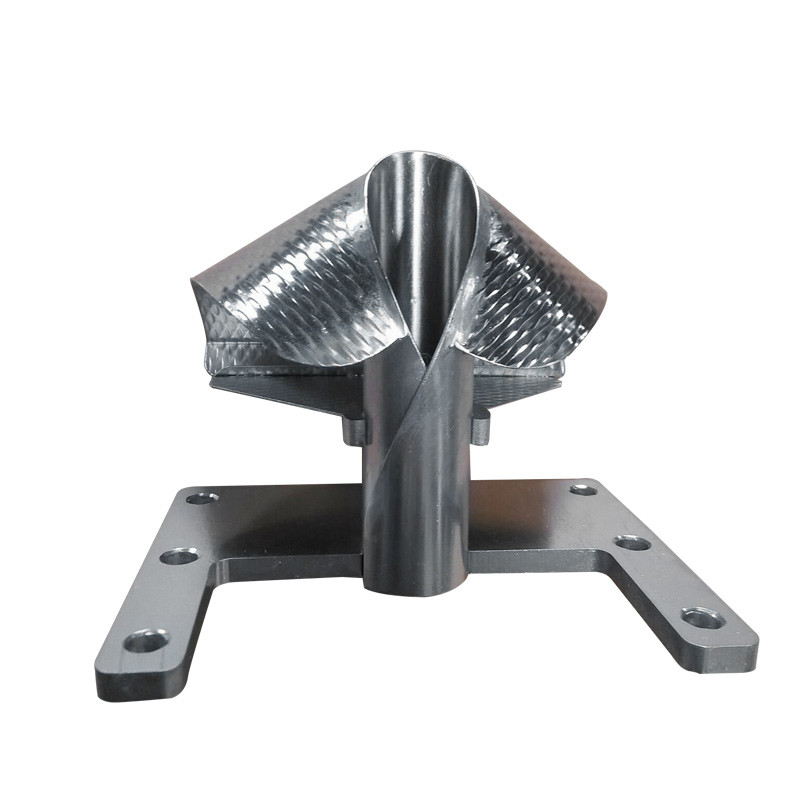

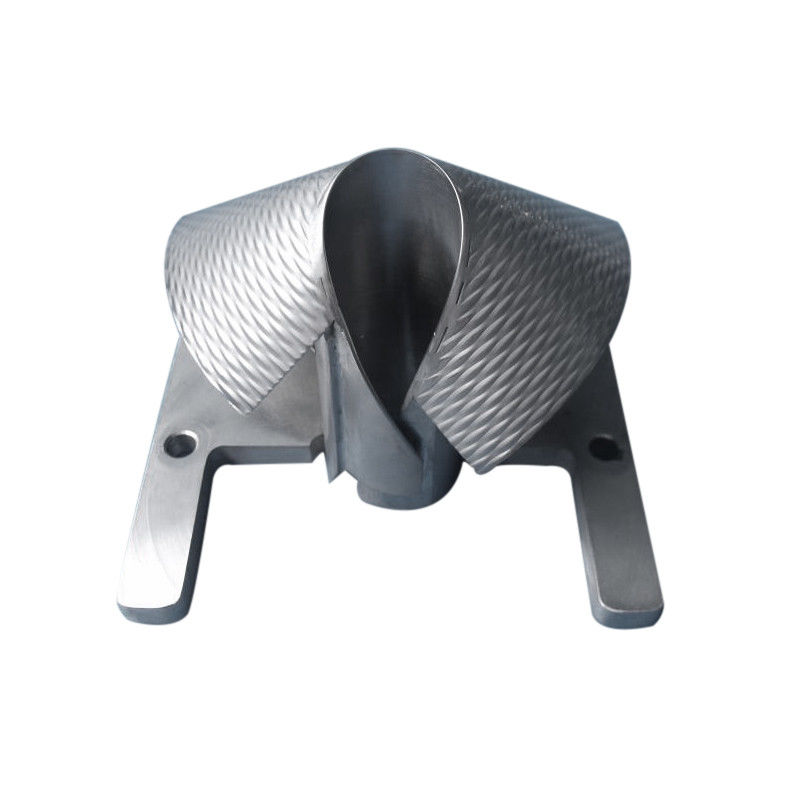

Packaging Bags Former Collar for Making Plastic Bags food bag formers

with good quality

Make Packaging More Easier

By applying the movable parts to the formers and collars, the usually closed forming shoulder is

rendered more accessible.

Under normal circumstances forming shoulders are closed for the filling tubes. Moveable front

parts improve accessibility.

The handling of film is much faster and safer, especially when used in multilane forming sets.

Structure

Our forming shoulders of the "easy-to-open" design consist of a body which is mounted on the

machine moveable front parts,

which can be opened and closed by a sliding mechanism

All parts are designed to move safely and without impacting any other parts when operated side by side.

Benefits

Reducing assembling time as well as time savings when changing and cleaning the parts on

account of the simplified

handling of the filling tube

suitable for multilane forming sets.

Faster replacing and cleaning. More convinent for handling.

Designed and manufactured to the requirements of your packing material, your packaging

machine and your product

guaranteed wrinkle free forming of your sample material

hold the highest precision by an end-to-end computer aided designing and manufacturing process

Besides an individual designed forming shoulder we offer a wide range of reasonably priced and

standardized forming shoulders.

| 1. Blanking |

Selecting material according the customers' request. |

| 2. Forging |

Increasing the density of the material. |

| 3. Tempering |

Lowering temperature for processing. |

| 4. Finishing machining |

Making the material shaped |

| 5. Inspection |

Checking the products if they are the same as the drawing. |

| 6. Hardening |

Increasing the hardness of products and the material. |

| 7. Annealing |

To incrase abrasion resistance, need to anneal thermal insulation for

long time.

|

| 8. Hardening and tempering |

Hardening and tempering the parallel of products for processing. |

| 9. Coarse grinding |

Coarse grinding the surface of products to be shaped. |

| 10. Accurate grinding |

Supergrinding to incrase the precision and the parallel of products. |

| 11. Testing |

Refusing the unqualified products into the market. |

| 12. Packaging |

Different products, different packaging |

All of our materials are bought from reliable suppliers, such as Baogang China, Yishengbai from USA.

And we also have material testing, to check if the materials are the correct ones. To make sure all of the

materials are qualified.

Professional manufacturer of industrial blades , packaging seal jaws, packaging formers, knives ,

Located in Shanghai City, China (mainland) , Zhijing has been committed to the research and development

of various industrial blades, the main products including: slitting machine blade, Slitter circular blade,

slitting circular blade, shredder blades ,shear blades, cut flat circular knife, crusher blades, shredder

blades, wood cutting blades etc .

Our packaging machinery seal jaws, formers and accessories have already surpass Germany’s

and Japan’s quality. What ever the parts you are looking for, we can make innovations and produce

for you. Reduce your processing lines’ costs, solve your packaging problems, make your products

with a better packaging.

Our company pursuit of "super-sharp, high-precision, extremely durable" knife philosophy,

dedication to create each piece of mechanical blade, from the first sheet to the first one million tutte.

Let's sophisticated technology and strict attitude to provide you with top service!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!