| 1. Blanking |

Selecting material according the customers' request. |

| 2. Forging |

Increasing the density of the material. |

| 3. Tempering |

Lowering temperature for processing. |

| 4. Finishing machining |

Making the material shaped |

| 5. Inspection |

Checking the products if they are the same as the drawing. |

| 6. Hardening |

Increasing the hardness of products and the material. |

| 7. Annealing |

To incrase abrasion resistance, need to anneal thermal insulation

for long time.

|

| 8. Hardening and tempering |

Hardening and tempering the parallel of products for processing. |

| 9. Coarse grinding |

Coarse grinding the surface of products to be shaped. |

| 10. Accurate grinding |

Supergrinding to incrase the precision and the parallel of products. |

| 11. Testing |

Refusing the unqualified products into the market. |

| 12. Packaging |

Different products, different packaging |

1. Material: Our materials are from reliable steel facories. Material quality warranted. We also have

material testing machine, to make sure all of the materials are the correct material we need.

2. Processing: We have been manufacturing blades for more than 20 years. We pay attention to

the micro places when processing. And we are keeping improving the blades cutting efficiency and

the technical solutions for clients.

3. Our service: Technical solutions, fast response for the products inquiry, assist clients' requirements

on the after sale service offered.

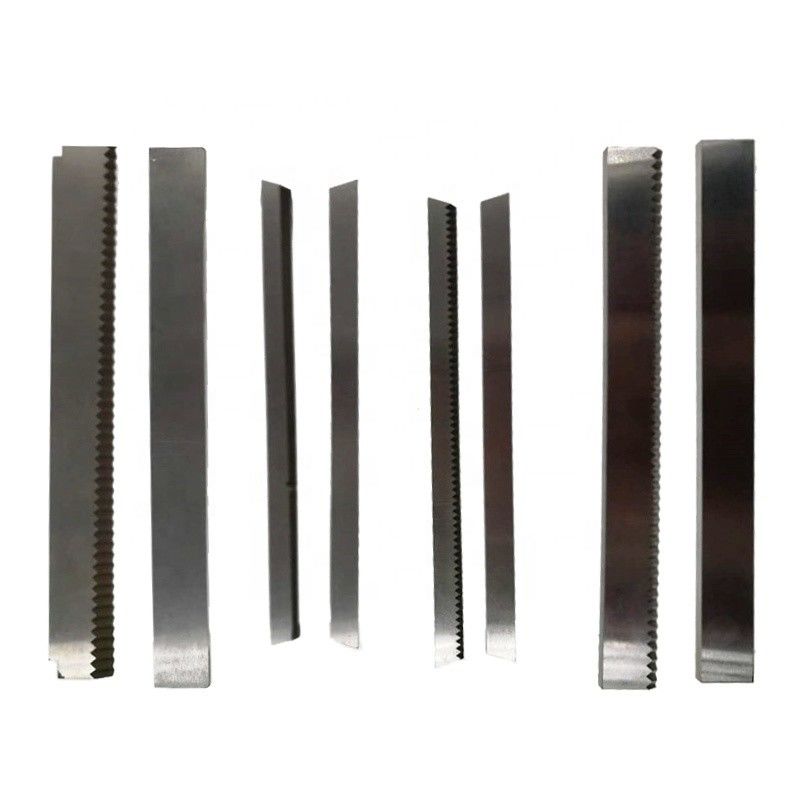

Professional manufacturer of industrial blades ,such as slitter blades, shearing machine blades,

cutting paper blades, crusher blades ,shredder blades etc , Located in Shanghai City, China (mainland) ,

Zhijing has been committed to the research and development of various industrial blade, the main

products include: slitting machine blade, Slitter circular blade, slitting circular blade, shredder blades ,

shear blades, cut flat circular knife, crusher blades, shredder blades, wood cutting blades etc .

Our company pursuit of "super-sharp, high-precision, extremely durable" knife philosophy, dedication

to create each piece of mechanical blade, from the first sheet to the first one million tutte. Let's sophisticated

technology and strict attitude to provide you with top service!

Service:

· Cutting Solutions

· We can offer solutions for your cutting requirements.

· Longer cutting life can reduce the costs of replacements

· Sharper cutting can make the cutting edge very smooth without any burs

· OEM&ODM for your special requirements

· Packaging Bag Former and Seal Solutions

· Free from tracking or vertical seal problems

· Solutions available for all types of manufacturing makes and models

· Choice of gas flushing options

· Reduced weight and cost compared to OEM alternatives

· Custom designed to suit all applications

· All hand and seal formations available

· Cost effective all-round solution

· Laser Engraving

We can engrave onto the products:

· Graphics

· Logos

· Serial numbers

· Codes

· Brand Names

· 2D Data Matrix Codes & UID Codes

· Fast delivery speed for your urgent need of the products. Only 3 to 5 days delivery for urgent products.

Ordinary lead time is within 20 days.

· Self-own the heat treatment furnaces plant.

Can do heat treatment as your special requirements.

· Material Testing Spectrometer

· We have the material testing spectrometer to check the raw materials, or clients’ samples’ materials.

· By checking the raw materials, we guarantee all of our materials are with reliable quality. By checking

clients’ samples, we will know to choose what kind of materials to improve the cutting efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!