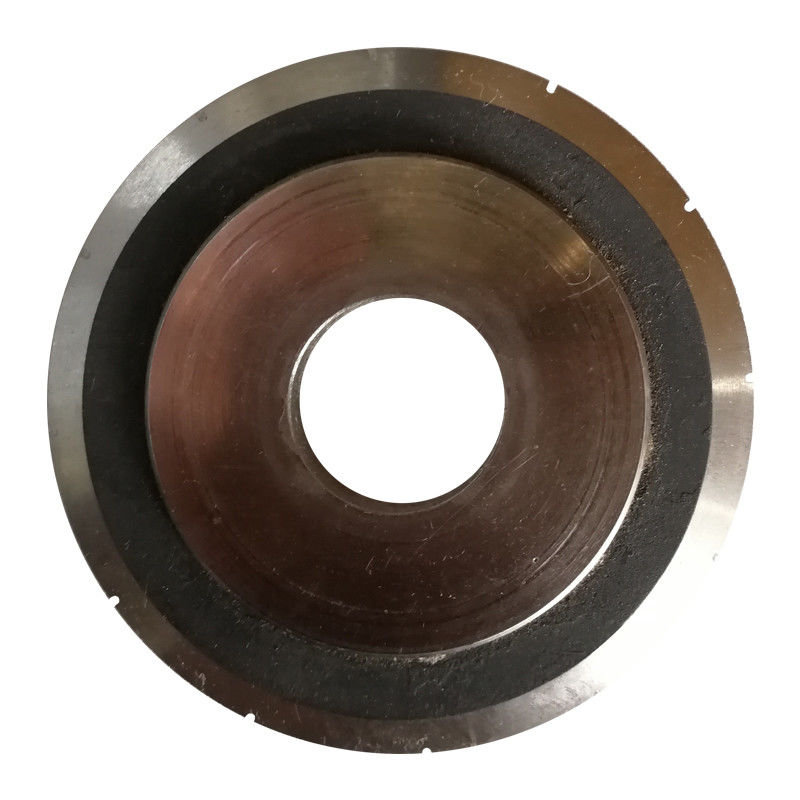

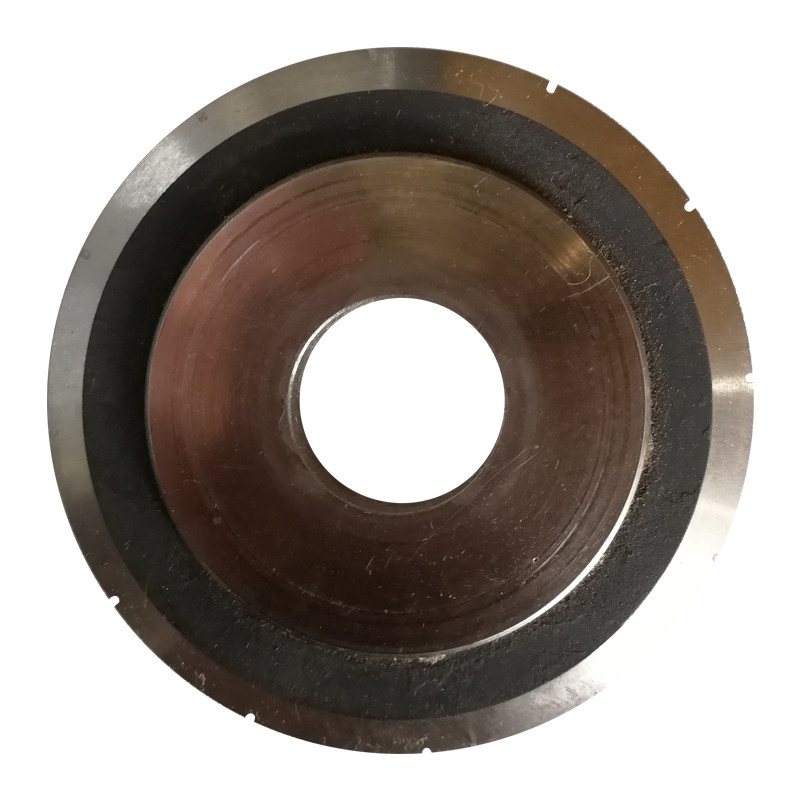

best price plastic film slitting pneumatic knife holder cutting

| 1. Blanking |

Selecting material according the customers' request. |

| 2. Forging |

Increasing the density of the material. |

| 3. Tempering |

Lowering temperature for processing. |

| 4. Finishing machining |

Making the material shaped |

| 5. Inspection |

Checking the products if they are the same as the drawing. |

| 6. Hardening |

Increasing the hardness of products and the material. |

| 7. Annealing |

To incrase abrasion resistance, need to anneal thermal insulation for long time. |

| 8. Hardening and tempering |

Hardening and tempering the parallel of products for processing. |

| 9. Coarse grinding |

Coarse grinding the surface of products to be shaped. |

| 10. Accurate grinding |

Supergrinding to incrase the precision and the parallel of products. |

| 11. Testing |

Refusing the unqualified products into the market. |

| 12. Packaging |

Different products, different packaging |

About any other knife found in your production facility

Choose the suitable materials , knife cutting edge styles, bevel angles, edge thickness, surface micro finish, hone technique, flatness . . . . all are

critical functions that will affect the knives and blades' performance in the machines processing operations.Wether what your machine knife

challenges are that we can build a knife for you that overcomes the challenges. We have more than 30 years' experience in all types of

applications engineering, Zhijing will help you optimize your machine knife performance.

Our machines can cut virtually any shape you can imagine without expensive tooling with advanced sawing and laser cutting capabilities. We

self owned the heat treating equipments ensures the processing controlled and consistently, that the machine knives we produce will give you

the best performance available.

Whether your knives are made from steel, carbide, stellite or ceramic, we can produce with these materials. We only use the best grades of

material available, formulated to meet the stringent demands faced by today’s processing requirements. Our machine knives are easy to set up

and tune by the high precise machines.

If you’ve been frustrated by performance issues or excessive downtime with your present machine knives,contact us. All Zhijing products are

designed to address both of those requirements – we sell improved productivity and reduced downtime, and that in turn drops right to your bottom

line. Remember, when you’ve got to make the cut, Hyde blades give you cutting edge performance.

Zhijing Precision Machinery (Shanghai) Co., Ltd. is manufacturing all kinds of industrial blades, knives, seal jaw sets,

bag forming sets and accessories, that are used in packaging industry, paper industry, plastic industry, steel industry, food industry,

medical industry, tobacco industry and other industrial usages.

These parts are produced according to drawings, product samples or specially developed by our engineers. Due to the use of high quality

materials and good workmanship, we are able to realize major lifetime improvements and reduce machine downtime for our customers.

In addition, our products have short delivery times with high reliability. Off-the-shelf or customized products are available from us with the

highest quality in China. In many cases we surpass the quality, delivery time and lifespan expectations of our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!